The components and operating methods of steel grating machines

Release time:2023-02-16

Steel grating machine working principle: The circuit is closed, so that the current is equal everywhere in the entire closed circuit; however, the resistance everywhere is different, especially the resistance at the unfixed contact point is the largest, this resistance is called contact resistance in physics.

Steel grating machine working principle: The circuit is closed, so that the current is the same everywhere in the entire closed circuit; however, the resistance everywhere is different, especially the resistance at the non-fixed contact point is the largest, this resistance is called contact resistance in physics.

According to the law of current thermal effect (also known as Joule's law), Q=I^2; ×Rt, it can be known that the current is equal, then the greater the resistance, the higher the heat generation, and the column head resistance is the largest when the electric welding is welding, so the heat generated in this part is naturally the most, when the column head presses the horizontal and longitudinal diameters together to release a large amount of heat, making the horizontal and longitudinal diameters melt and bond instantly.

Steel grating machine components:Longitudinal feeding mechanism: The primary gear elements and electronic components are manufactured in Europe or Asia; Longitudinal material rack: Designed and manufactured by professional engineers; Welding system: Using special copper strips, greatly improves conductivity and saves energy; Cable welding: Using special copper strips, greatly improves conductivity and saves energy; Professional welding transformer control system: Uses interference servo motors and controllers. The Brand of control system can be configured according to customer requirements.

Operating methods of steel grating punching machine

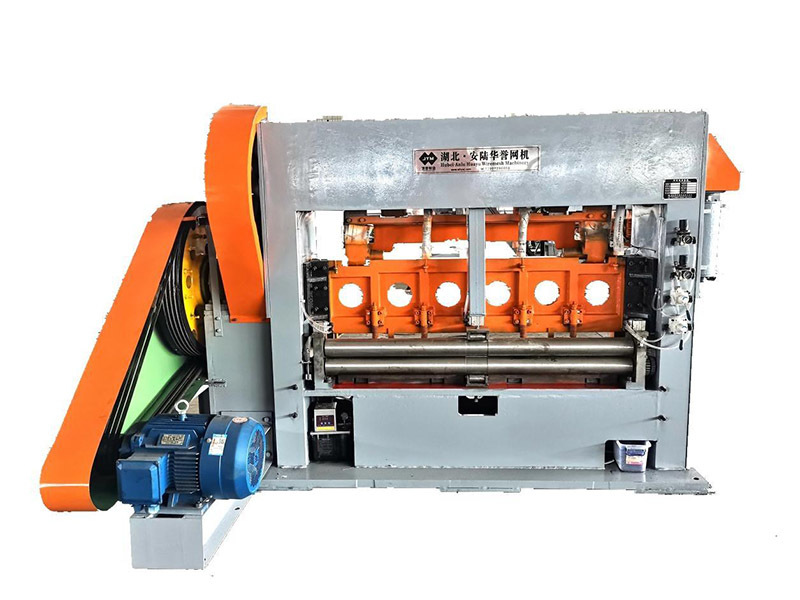

Steel grating punching machines are researched and developed to achieve high-efficiency production of wire mesh machinery, based on the rapid development of the wire mesh market and actual needs. Steel grating machines are divided into two types: stretched mesh and punched mesh. Also known as steel grating punching machines, diamond mesh machines, stretching mesh machines, round hole mesh machines, and shaped hole mesh punching machines.

The new type of steel grating machine, in order to meet the needs of actual production of steel grating, independently designed a digital numerical control and stepless frequency conversion speed regulating motor to achieve a smoother, more beautiful, and smaller rib mesh surface with high added value.

JQ25-25 type steel grating machine, JQ25-63 type steel grating machine, JQ25-100 type steel grating machine, JQ25-100 2.5 type steel grating machine, JQ25-200 type steel grating machine. These models can punch various metal plates with a thickness of 0.1mm-8mm and a width of 100mm-2500mm, and the mesh size can be changed by changing the mold.

The steel grating machine punches and shears various materials of steel plates or iron plates, and then stretches them into diamond-shaped mesh steel grating, which is called diamond steel grating. Another type is that it punches holes in the steel plate to form round holes or various shaped mesh holes.

Steel grating machine operating methods:

Steel grating machine operation types can be divided into electric control and numerical control.

The perforated metal machine is a pressure punching machine series steel grating machine, which can punch various mesh steel plates after changing the mold, including round mesh holes and shaped mesh holes of various sizes.

Generally, the production of steel grating can be completed through the following steps: pre-test preparation, machine adjustment, and steel grating production.

Previous Page